HIGH-PERFORMANCE STEEL PARTS

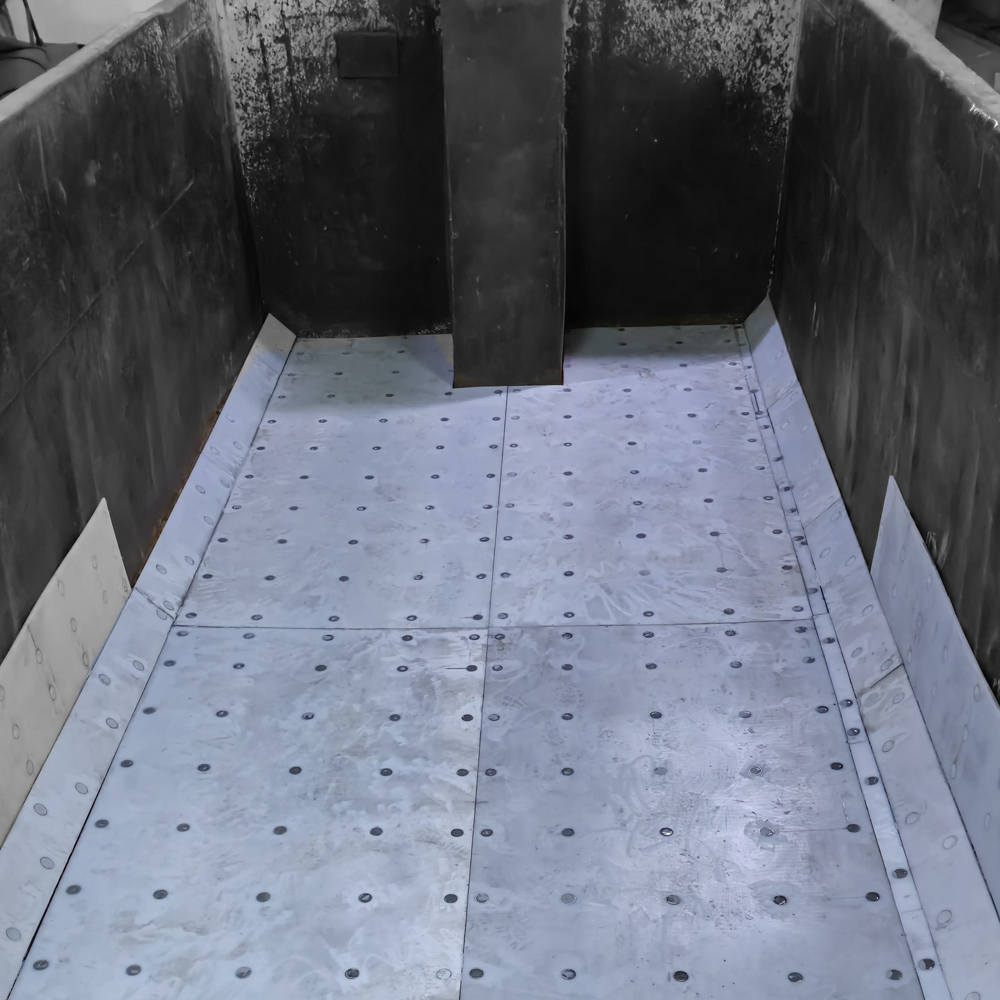

HOPPER PROTECTIONS

In demanding work environments such as quarries and roadworks, tipping hoppers are exposed to constant impacts, abrasion, and severe friction. To meet these challenges, STAAL has developed reinforced protections made of SSAB Hardox steel, a material globally recognized for its exceptional wear and impact resistance.

These solutions are designed to strengthen the most critical areas of the hopper, significantly extending its service life and minimizing repairs and unplanned downtime — delivering performance up to eight times higher than conventional steels.

The result is clear: greater productivity, lower maintenance, and real protection for your investment.

Additionally, high molecular weight polymer (PE-UHMW) liners are available, ideal for minimizing material adhesion and preventing corrosion, especially under humid or chemically aggressive conditions.

A robust, practical, and durable solution — designed for those who work hard every day.

CONTACT AN ADVISOR

Catalogs |

||

|---|---|---|

| No catalogs available |